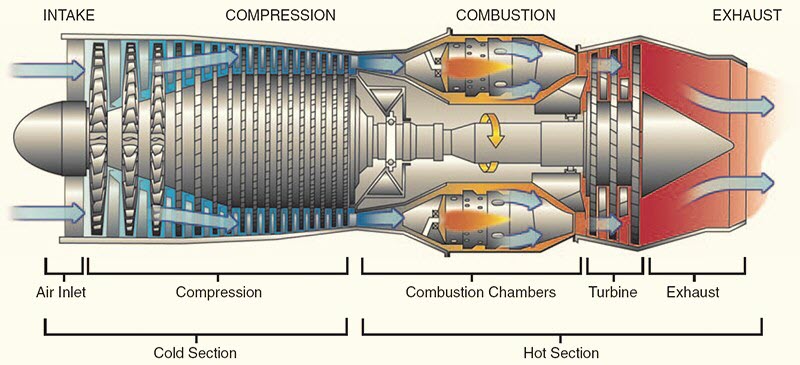

Today’s Tech Tip is on selecting high-temperature materials to meet the unique sealing needs of the aerospace industry. This topic seems especially appropriate given the recent celebration of Earth Day; an event that is synonymous with environmental protection. Sealing is itself a way to protect the environment; especially when you are sealing chemicals or oils as in the case of a turbofan jet engine where the high temperature makes this task more challenging. Turbofans are the most-common type of jet engine since they are used in commercial aircraft, transports and military aircraft; therefore, selecting the right high-temperature material is essentially an automatic concern for aerospace designers, along with reducing total weight for better fuel efficiency.