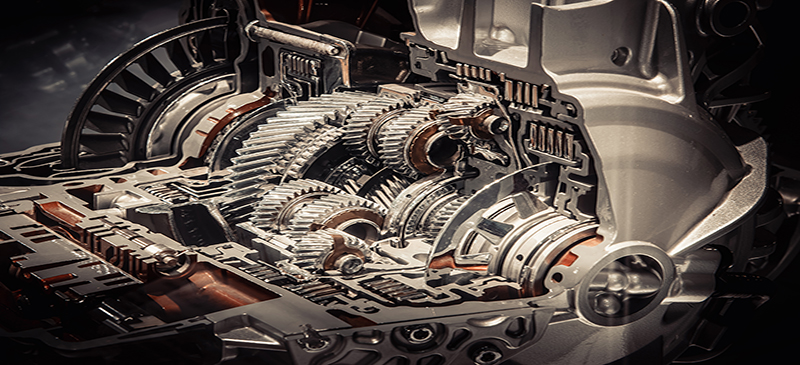

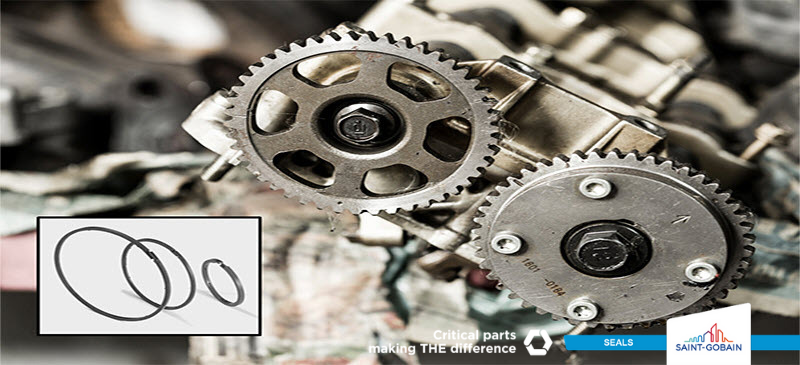

For most of the world, an automobile is a common item that is used every day and part of our daily lives. That is why automotive manufacturers take the care to make sure everything is in working order whether it be the engine, tires or brakes. One of the most important parts of a car is the transmission, which provides power and handles control. With people being in the driver seat at least one hour per day, the powertrain system does play a very important role. Within this critical powertrain system are seals that work to improve the quality of shifting gears, acceleration and maneuverability so the driver has a smooth and comfortable ride. Therefore, selecting the right seal does make a significant difference for both automotive manufacturers and the consumers they serve.