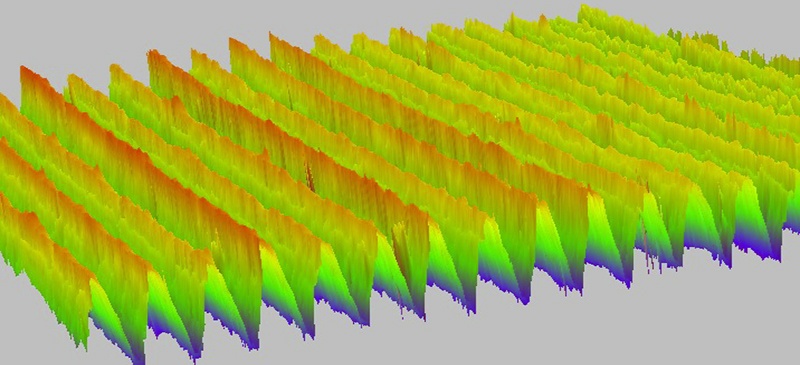

In our last oil and gas blog post, we discussed four key factors to consider when selecting sealing solutions: application, working conditions, compliance and fugitive emissions and proven design. Behind these four factors are other design engineering elements that go into developing the seal to precisely fit and perform optimally in a certain environment. Similar to the industry’s deeper investigation into complex downhole reserves and urgency to solve high pressure, high temperature (HPHT), cryogenic temperatures, heavy oil and other challenges, we are also delving deeper into an engineering element that may be overlooked or underestimated, which is how the right surface finish can make or break a seal’s ability to function properly.