For most of the world, an automobile is a common item that is used every day and part of our daily lives. That is why automotive manufacturers take the care to make sure everything is in working order whether it be the engine, tires or brakes. One of the most important parts of a car is the transmission, which provides power and handles control. With people being in the driver seat at least one hour per day, the powertrain system does play a very important role. Within this critical powertrain system are seals that work to improve the quality of shifting gears, acceleration and maneuverability so the driver has a smooth and comfortable ride. Therefore, selecting the right seal does make a significant difference for both automotive manufacturers and the consumers they serve.

In powertrain applications, rotating connections are used as a common solution for oil pressure supply to clutches and actuators. In most cases, they contain two rectangular seals which are located in grooves in the rotating shaft that are placed on either side of the oil-feed channels. The seal design is quite similar to piston rings but instead of a reciprocating motion, the shaft rotates. Originally grey cast iron materials were used but subsequently substituted by PTFE materials in the nineties. Today, these type of seals are almost exclusively made out of high-temperature thermoplastics that outperform past solutions with increased load capacity and lower drag torque and leakage.

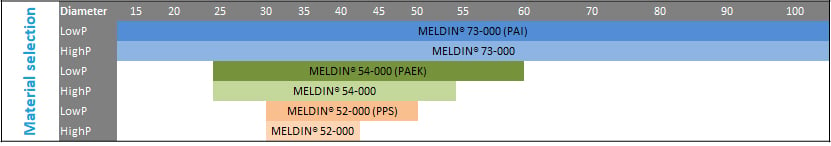

Polymers such as polyphenylene sulfide (PPS), polyetheretherketone (PEEK), thermoplastic polyimides (TPI) and polyamideimide (PAI) are combined with various fibres and additives to produce a wide range of compounds. As such, selecting a material for a new application can be quite a challenge. You must consider such parameters as seal diameter and pressure range as shown in the below orientation (Figure 1) with Saint-Gobain APS’ Meldin® thermoplastic materials. These solutions have been selected for transmission applications due to their outstanding temperature and oil resistance.

Figure 1

Figure 1

For a more accurate selection, it is key to review potential failure modes of such seals. These include the following cases.

- Thermal failure

- Wear

- Mechanical failure

Thermal Failure Case

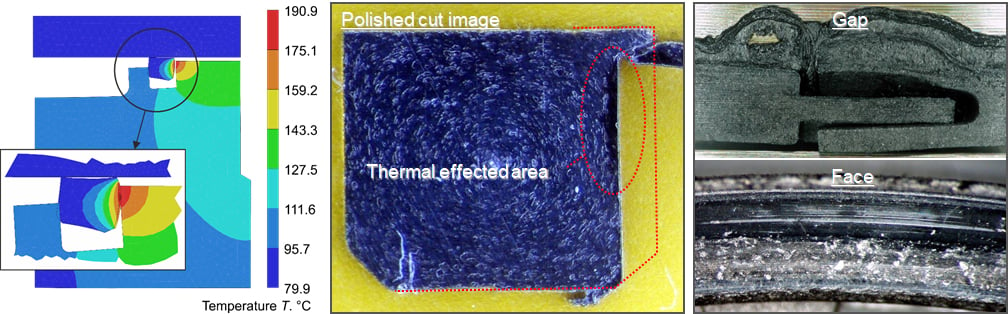

In the event of a thermal failure, the seal ring surface will soften or melt due to the friction-related temperature increase. This often cuts off the oil from sealing contact, which intensifies the friction heating effect and the component ultimately loses its geometry and thus its sealing function. The critical contact area in the groove is nearby the edge of the shaft (Figure 2) where the highest pressures and temperatures occur.

Figure 2

Wear Case

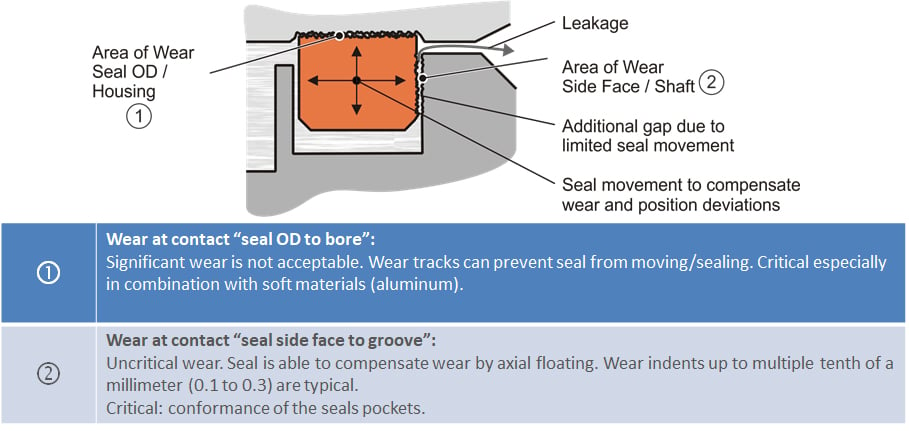

As long as the sealing rings are used in combination with hard mating surfaces (steel), wear occurs dominantly on the seals’ side face. Wear depth values of up to 0.1 mm on smooth and 0.25 mm on rough surfaces over lifetime are common and compensated by the self-adjusting design (Figure 3). Problems are rather rare in practice and can be easily remedied by adjusting the roughness. Basically, a harder counter-surface requires a smoother finish.

Figure 3

Soft counter surface materials (aluminum, gray cast iron) require a careful check. For such combinations wear of the metal part itself can be a risk as well. Such applications require an adapted sizing or a special seal design that prevents movement between seal and the soft counterpart.

Mechanical Failure Case

Mechanical problems typically occur during installation for which the sealing ring has to be expanded beyond the shaft diameter. If the expansion exceeds the elastic limit of the material, it breaks. Typically, the material fails in the weakest area, the injection point, or if present, the weld lines. The installation of seal and shaft in the surrounding bore can be problematic as well. If the sealing ring protrudes too far, it will be sheared off and can no longer fulfill its function.

As a result, unreinforced materials with a high elongation at break are preferred for small seal rings (<30 mm diameter). For larger seals, a small amount of fibre reinforcement is advantageous and allows for small cross-sections with sufficient robustness and tight tolerances.

The Practical Approach To Seal Material Selection

Taking a practical approach to material selection starts with reviewing the thermal failure case as this dominates the selection process. Based on a given material with reasonable safety versus melting, the assembly process can be reviewed. A full stack analysis of all mating components and involved bearing is needed for this. Finally, the wear is estimated based on empirical data. This approach may have to be run through iteratively several times until a suitable material is found.

Of course mould filling issues can also impact the selection. In case of problems, these issues can be eliminated by adapting the seals cross-section and therefore only have an indirect influence.

Saint-Gobain APS’ team has conducted a detailed thermal failure case study, which can be found in their technical white paper: “Critical Polymer Seals In Transmission Applications: Selecting The Appropriate Seal Material In Powertrain Systems.” The technical paper shares further analysis as part of an extensive test series performed with various designs and materials that include surface temperature measurements.

If you have any questions, please contact one of our experts!