Have you heard the expression, “We travel not to escape life but for life not to escape us”?

Imagine life without mobility and the ability to expand our possibilities, connect, dream, communicate, gain knowledge and advance.

At Omniseal Solutions™, we have been powering mobility in many ways through our polymer seals, metal seals, and specialized material solutions such as carbon fiber composites, PTFE and polyimides.

With over 4,000 employees and a global presence in 14 countries, we hail from an even deeper history and stronger manufacturing background with our parent company, Saint-Gobain, created over 350 years ago. As a developer of innovative photovoltaic glass to smart insulation systems, water supply systems and more, Saint-Gobain is one of the top 100 industrial groups in the world with over 1,000 manufacturing facilities, 180,000+ employees and one in four of its products sold today that did not exist 15 years ago.

What is our place in relation to the world we live in? Discover why we focus on solutions that improve and protect our daily lives and keep us moving and how we continue to concentrate on transforming and growing, our customers, and giving back.

Engineering “Moving” Solutions Is Our Inspiration

Continually advancing solutions to make life more comfortable, safe, and sustainable, has been at the forefront for Omniseal Solutions™. With higher-performing, stronger, lighter-weight, and more sustainable materials, we help partners to push the limits to improve everyday life.

One way we focus on our customers and innovation is by structuring our company to address market needs, anticipate emerging needs, and shorten development time.

As with our parent company, our R&D department comprises of local teams in addition to a network of global transversal R&D centers. These transversal centers acquire core technologies, work on longer-term, more fundamental projects, focus on innovation and global requirements, serve as hubs for academia and external contacts, and aim to attract and develop talent to serve Saint-Gobain’s businesses worldwide.

Omniseal Solutions’ R&D local teams can be found in the following locations: Garden Grove, California, USA; Kontich, Belgium; Bristol, Rhode Island, USA; Saltillo, Mexico; Willich, Germany; and Wertheim, Germany. R&D resources are also in three corporate transversal R&D centers in Northboro, Massachusetts, USA; Shanghai, China; and Chennai, India.

With regional offices teams/centers dedicated to our business and customers, we are able to identify and supply local needs. By drawing on solutions and skills from our R&D centers throughout the world, we can provide a better and quicker response. And our transversal centers allow us to focus on longer-term innovation to address customers’ needs today and into the future.

As just one example of our customer-centric goals, we recently announced numerous advances at our Kontich, Belgium R&D site to specifically address advanced polymer needs in aerospace and life sciences, in addition to supporting the oil and gas industry. Along with expanding the site’s R&D, testing and customer onboarding areas (including numerous other advancements throughout the years, with the R&D laboratory expanded in 2017 and a number of other manufacturing upgrades made in 2016), the Kontich initiative also establishes sales and engineering around customer markets with a focus on customer needs in design. Omniseal Solutions’ Kontich office is also moving toward greater digitization for increased efficiencies and to maximize employee productivity and has instituted a number of practices to entrust employees to be more agile and reduce reaction time to problems as well as elevate larger issues where necessary.

Specialty Materials Making THE Difference

Another way we go beyond is through our passion for materials. We share a commitment to pushing limits and possibilities. We are committed to developing even lighter materials in commercial airplanes, cars, and electric vehicles reducing emissions and increasing efficiency; increasing recyclability of materials in rockets in space; developing even more durable, longer-wearing parts to help prevent downtime in manufacturing, and ensuring greater reliability in parts in healthcare devices that people rely on.

How do we do it? Through our solutions portfolio and expertise

- With Omniseal® spring-energized seals that have been used since the first space flights in support of NASA and their vision to go further in the universe. These popular seals are recognized for their high-performance strength, and for offering ultra-low friction and chemical compatibility in extreme hot or cryogenic temperatures.

- As the only source of genuine Rulon® blended PTFE filled materials. This family of materials is in the top-tier of high-performing plastics and is known for high wear life, excellent abrasion resistance, chemical inertness, and the ability to operate in extreme temperature and pressure ranges. Several grades are FDA-approved for use in critical medical devices and food and drug manufacturing.

- With carbon fiber components, including Wearcomp® solution, that offer a low coefficient of friction, outstanding mechanical strength, and wear resistance at high temperatures.

- Through a diverse family of engineered thermoplastic Meldin® products and top thermoset polyimide materials drawing on unique characteristics proven for specialized applications in aerospace, automotive, electronics, and other industries where high thermal resistance and good mechanical properties at high temperatures are a requirement.

- With metal seals (including C-seals, O-seals, E-seals, face seals, radial seals, combustion seals, and more) that address the highest temperatures and pressure fluctuations and requirements for the most demanding applications

Our cutting-edge material development is combined with industry expertise and a consultative approach to work with customers to determine the best sealing and material solution to address their specific needs. We then leverage leading manufacturing techniques, a commitment to standards [ISO 9001,14001, 9100, 16949, 5S, Kaizen, 6 Sigma, World Class Manufacturing, NORSOK and API, to name a few], and a focus on quality and testing and simulation to ensure reliability.

Powering & Protecting Mobility in Everyday Life

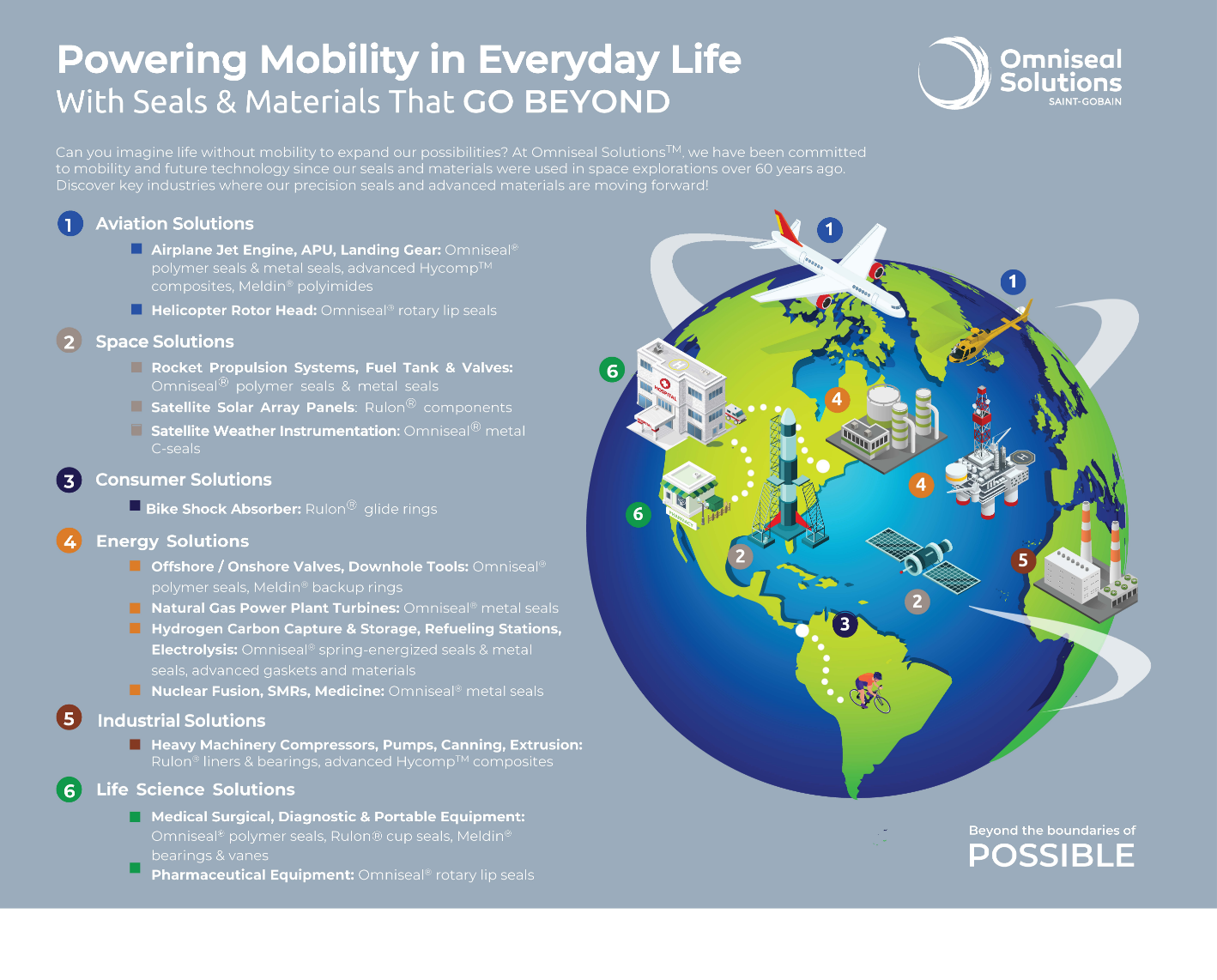

Where are our solutions “moving” you? You may be surprised where we are and what we protect...

Explore our infographic to see where we help power mobility in everyday life.

- Aerospace – Omniseal® polymer spring-energized seals and ASE and HTMS metal seals are used in commercial and general airplanes in jet engines, APUs, landing gear, actuators, and bleed for their high temperature and pressure benefits. Omniseal® spring-energized seals and rotary lip seals are used in helicopter rotor heads to prevent oils and greases from leaking and contaminants such as ice, water and dirt from coming in.

- Space – with Omniseal® spring-energized seals drawing on 60 years in this industry and ASE and HTMS metal seals addressing cryogenic to 1,950ºF temperatures in propulsion, ground equipment, payload, and structures and tanks in satellites, rockets, and other space applications. Check out our space journey here!

- Energy – Omniseal® spring-energized seals have been used in the oil and gas market since the 1970s and are used in onshore and subsea drilling, production, and transport. Our Meldin® polyimide solutions offer high pressure and high temperature properties in this industry. Our metal seals help to improve efficiency at nuclear power plants as well as in power generation systems with natural gas turbines.

- Life Science – Omniseal®, Rulon®, and Meldin® high-purity solutions address stringent requirements and support healthcare professionals with surgical tools and analytical instrumentation such as laboratory and in-vitro diagnostics as well as end users in home healthcare with portable oxygen concentrators and portable insulin delivery pumps.

- Industrial – Wearcomp® liners and bushings and ’ Rulon® and Meldin® parts are used in machinery in compressors, pumps and valves, dispensing equipment, and steel production in industrial plants that manufacture just about everything we use such as aluminum cans.

- Transportation & Consumer – Omniseal® and Meldin® solutions are used in exhaust management, powertrain and braking system, active safety, driving comfort, and electric drive automotive applications. We have supplied over one million metal lip seals to the diesel truck engine industry. Rulon® glide rings make bicycles more comfortable and safe.

Leaving Things Better Than We Left Them

In addition to designing solutions that protect us, we also manufacture materials that protect our environment and help our partners build better solutions, improving the planet.

By supporting sustainability

- Our materials support renewable energy efforts and more efficient processes. Our seals are used in energy-efficient wind turbines and in DyeCoo environmentally-friendly waterless dyeing technology that save billions of liters of water and prevent billions of gallons of toxic chemicals from being dumped into waterways.

- Our Stem energy savings project at the Garden Grove site leverages artificial intelligence with access to the world’s largest energy storage network to shift times electricity is produced and used to be cleaner, put less strain on the grid, and decrease costs.

By working with communities

- We work with local non-profit organizations like Community Action Partnership of Orange County and the Boys & Girls Club.

By supporting education

- Samples of our Omniseal®, Rulon®, and Meldin® sealing and polymer parts are on display at Greentown Labs' Cleantech Center for Startup Growth to support growth for future energy and sustainable solutions.

- We host students at our sites to familiarize them on the manufacturing industry to inspire their dreams of building a better world. One of our favorite visits was from the Escolapias School at our La Rioja, Spain, site.

- We reach out to local universities to train students and support their interest in engineering.

- We sponsor student engineering – in space exploration, see what we achieved with KA-Racing!

Throughout all we do, advancing mobility in our lives and supporting our customers have been our focus yesterday, today, and as we look to the future. Please contact our team of engineering, R&D and manufacturing experts to continue powering.